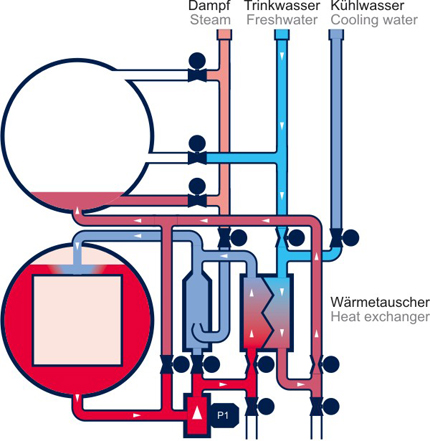

Heat Exchanger

for constantly renewed process water

During the thermoprocessing of packaged foods the process water can get contaminated by defective packaging containers or adhering product overrun. In conventional full water immersion retorts the process water is re-used, so the substances can accumulate and contaminate packaging containers as well as process vessels.

Original or retrofit equipment

The problem solution is based on the installation of a heat exchanger. In the illustrated first cooling phase, it transfers the energy from the process water to the fresh water, replenishing the storage vessel. For the second cooling phase, water can be used from a cooling circuit. After cooling down, the process water is discharged into the drain. The packs and the retort are exposed only to constantly renewed water that is sterilized during the process. Chlorination is unnecessary because no contaminated water is recirculated.