Control and Documentation

Designed Systematically

- Intelligent process-control, simple to operate

- For all retorts, flexible upgrading

- Efficient network and SCADA solutions

- Flexible upgrading for STOCK and other brand retortse

Production safety as a result of a perfected conception

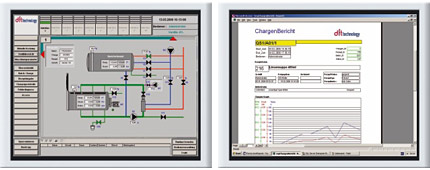

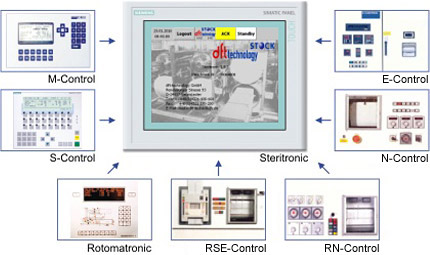

Control, documentation and SCADA systems - dft technology supplies a system of perfectly coordinated components for retort plants.

Outstanding production safety is realized by separation of machine control from the data management, as well as office network from control network.

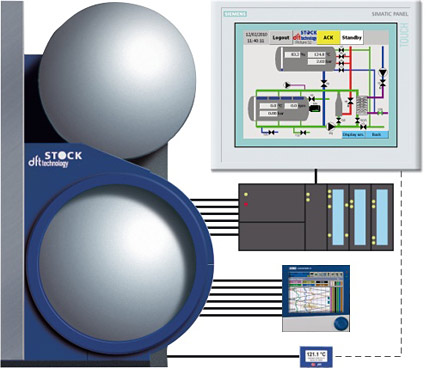

Steuerung: SIEMENS Touch-Panel TP1200 und S7 SPS

The SIMATIC 12.1" touchpanel TP1200 is the comfortable instrument for the input and operation of the programs. The clear layout of the operating interface simplifies the operation of complicated full-immersion rotation retorts.

Programming and operation are menu oriented and self explaining. The access to the different menu levels is locked by operator code. This restricts manipulation of the process and parameter changes to authorized personnel only.

Programming and operation are menu oriented and self explaining. The access to the different menu levels is locked by operator code. This restricts manipulation of the process and parameter changes to authorized personnel only.

The flexible programming capabilities enable for reproduction of all imaginable process sequences and sterilization of the most sensitive packagings and products.

The SIEMENS S7 PLC controls the process via software controller, and also carries out the program management. The system is power failure safe.

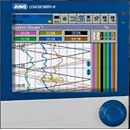

Documentation: JUMO LOGOSCREEN nt

The paperless recorders stand out through their innovative operating concept and high standards of security to prevent unauthorized access and manipulation of the stored data. In the LOGOSCREEN nt, data can be visualized in process images as measurement curves, as a bar graph or in alphanumerical form.

The paperless recorders stand out through their innovative operating concept and high standards of security to prevent unauthorized access and manipulation of the stored data. In the LOGOSCREEN nt, data can be visualized in process images as measurement curves, as a bar graph or in alphanumerical form.

Powerful PC programs are available for analyzing and evaluating the archived data, and for configuring the LOGOSCREEN nt.

Reference thermometer: ELLAB ETI

![]() The ETI is a high quality digital temperature-indicating device designed for displaying and documenting the processing temperature in retorts. It complies with FDA 21 CFR Part 113. Due to the accuracy of ± 0.1°C it is the up to date alternative to mercury thermometers, and does not constitute a potential source of mercury contamination.

The ETI is a high quality digital temperature-indicating device designed for displaying and documenting the processing temperature in retorts. It complies with FDA 21 CFR Part 113. Due to the accuracy of ± 0.1°C it is the up to date alternative to mercury thermometers, and does not constitute a potential source of mercury contamination.

An output channel allows for automatic alarms via the Steritronic.

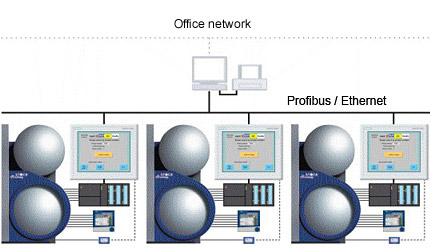

Network and SCADA System

For recipe management and documentation Steritronic controls may be connected to a control network and host PC via Profibus or Ethernet. Optional links to factory or office networks are protected by firewalls.

dft technology offers standard software for data acquisition and recipe management within the food industry. WIN CC for visualization and communication with the retort controls, the integrated Microsoft SQL-Server for comprehensive process data and the universal reporting system of Access make sure that the production line runs absolutely reliable.

Upgradable Innovation

Modern controls offer significant improvement, flexibility, product quality and safety as well as process fidelity, even for used machines.

The Steritronic is the compact innovative solution for autoclaves of all makes.

Please get in touch with us, we have the right solution for you!