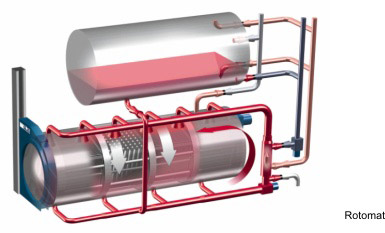

Automat / Rotomat:

The Universal Full Water Immersion Retort

- Product Quality - one system for all requirements

- Variety of containers - flexible without compromises

- Food safety - oxygen free processing

Full water immersion counterpressure retort concept

- Energy contained in the storage vessel allows for an extremely short temperature come-up-time.

- Water envelops the containers - even temperature penetration into the product from all sides.

- Optimised water circulation system guarantees homogenous temperature distribution.

- Buoyancy in full water immersion relieves sensible containers as semi-rigid trays, pouches etc.

- Counterpressure control with steam in the storage vessel avoids pressure peaks and minimises stress to packaging material.

- Containers are at no process phase in contact with air - oxidation of products is securely excluded.

- Even, gentle but nevertheless fast cooling avoids thermal shock and post-sterilisation cooking effect.

- High temperatures, transferred swiftly into the product, ensure that the required lethality effect (F-value) is obtained as fast as possible.

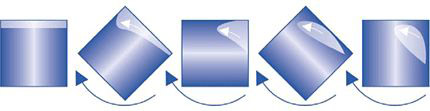

Rotation

- Forced convection due to rotary operation accelerates the heat transfer to the coldest spot in the containers, even with products of higher viscosity.

- Short process times preserve natural quality, vitamins and nutritional values.

- Agitation of the product during heating prevents burning on the container walls.

- End-over-end rotation in an intensely mixed process water environment with its optimal heat transfer ensures the HTST (high temperature - short time) processing of most products.

Procedure animation

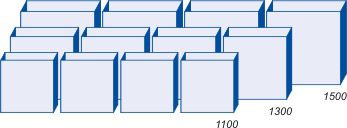

Variants for all requirements

Various as our customer's requirements regarding capacity and sterilisation process - our range of full water immersion retorts: from the 2-cage autoclave for small batches of high quality "delicatessen" up to large capacity retorts for vegetable products in pouches.

The semi-immersion-rotary process, an option in each Stock Rotomat, meets highest requirements with reference to homogenous temperature distribution even with containers of a geometry, which otherwise impedes water throughflow.

| Type, Diameter | Cages/gross volume litre | ||

|---|---|---|---|

| Rotomat SRX 1100 | 2/730 | 3/1095 | 4/1460 |

| Rotomat SRX 1300 | 2/1030 | 3/1545 | 4/2060 |

| Rotomat SRX 1500 | 2/2050 | 3/3075 | 4/4100 |

| Automat SAX 1100 | 2/730 | 3/1095 | 4/1460 |

| Automat SAX 1300 | 2/1030 | 3/1545 | 4/2060 |

| Automat SAX 1500 | 2/2050 | 3/3075 | 4/4100 |

Economic and clean

The use of heat exchangers significantly simplifies the incorporation of the retorts into energy and water recovery systems:

- Indirect heating = recovery of condensate

- Indirect cooling = multiple use of cooling water, cooling in a sterile environment

High performing, flexible and economic:

Automated Batch Retort Systems

Manual loading and unloading of large capacity retorts requires great physical exertion. In this regard automatic handling systems from dft technology offer a substantial contribution of facilitation. A wide range, from manually operated packing supports to semi-automatic and fully automatic batch retort handling systems provides adequate solutions for any requirement.

Simplification of work flow with guaranteed flexibility!