Spacer Mats for Autoclave Cages

In order to accommodate them space-saving and stable in layers, perforated spacer mats are used, with which the individual layers are separated.

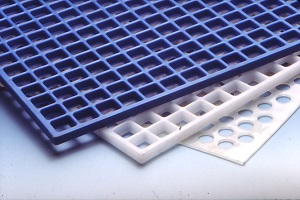

For this, at first glance simple task, there is an astonishingly wide selection of different spacer mat models and variants available (Fig. 1).

It pays to think a little bit about the selection of the most suitable spacer mats, because they have an influence on the loading and unloading, the capacity and – depending on method – also on the sterilization process.

Spacer mats can differ in:

• their material (e.g. PP, PPH, PPT, silicone, aluminum, composite mats from PP and EPDM or from aluminum and PP)

• their strength in mm (selectable between 3 and 12 mm)

• their design in relation to the handling

• their design in relation to the water guiding

Fig. 1: Some examples of different spacer mat models

The material:

The simplest and most cost-effective spacer mats are made from perforated polypropylene plates. For sensitive containers (such as glass with screw caps), however, softer silicone mats are often used, to avoid scratch marks on the glass lids. If, on the other hand, the spacer mats are to be both soft (avoidance of scratch marks) and dimensionally stable (especially important for automated loading), one sometimes resorts to composite mats. Here, it must be ensured, however, that the materials selected have as similar an expansion behavior as possible at changing temperatures.

The strenght in mm:

Although their use is necessary, each mat naturally takes up valuable space in the cage at the expense of capacity (Fig. 2). Nevertheless, thinner here is not always better; thicker spacer mats usually allow a better flooding of the containers and are therefore initially recommended. Only if their use would result in having to waive a product layer, you should use a suitable lower strength.

Fig. 2: Spacer mats in different strength

Design in relation to the handling:

Basically, the manual handling of spacer mats is the easier the more stable they are and the less they weigh. This usually speaks for thin polypropylene mats. In the standard these have a perforation, which spares only the mat edge. However, if the spacer mats are to be used automatically, they need suction surfaces for the arms of the robot. Depending on the size of the autoclave cage, these are usually 4-6 perforation-free areas (Fig. 3). For very small containers, however, there is the risk of umbrella effect directly below the perforation-free areas. This must be taken into account in the packing scheme. Alternatively, spacer mats with special water guiding come into the question (see below).

Abb. 3: Zwischenmatte mit Ansaugflächen für die automatische Beladung durch Roboterarme

Design in relation to the water guiding:

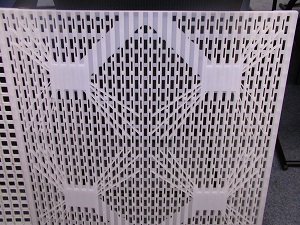

Regardless of the chosen sterilization process, it is always important to ensure an adequate and homogenous flooding of the containers. Many factors play a role here. Depending on the container type and geometry, a suitable procedure (stand/rotation, full water/sprinkling/spraying, additional use of steam) and a suitable packing scheme must be selected. Special spacer mats can support very well here, e.g. through transverse water channels (Fig. 4).

Fig. 4: Spacer mat with transverse water channels

General recommendations:

Spacer mats should not be stacked on top of each other, because due to the inevitable play the hole patterns are not exactly on top of each other, so that the flow cross sections are reduced. In order to compensate for larger height differences between the upper product layer and the cage edge, product-specific designed grid frames are recommended instead.