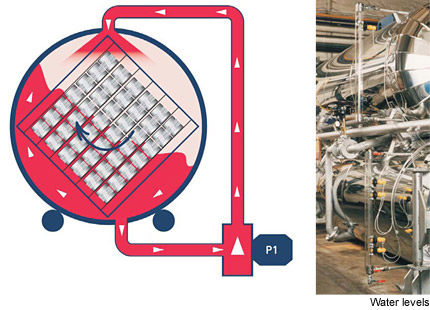

Energy Saving: Half-water-immersion Sterilisation

for Increased Efficiency

- Economization of approximately 30% steam and water

- Batch times can be reduced

- Intensive and even processing can improve product quality

Retrofitting the half water immersion mode

Full-water-immersion retorts such as the STOCK Rotomat have a universal operating range, and can be used for the sterilisation of almost every type of product. On the other hand, this type of process has a higher energy and water consumption compared to alternative methods. Because of this, STOCK offered the equipment for half-water-immersion processing for decades. This process saves considerable amounts of energy and water, furthermore the dipping of the containers intensivates the interchange of heat. Batch times can be reduced, and the quality of the products can be improved.

For selection of half or full water immersion, a toggle will be mounted in the additionally provided switch box. The retort control usually will not be modified. Pressure and temperature programmes can be retained without changes.

The system pressure must be stabilized with compressed air. If your water treatment has given the vessel sufficient protection up to now, one can assume that the use of compressed air will cause no damage. To be on the safe side, specialists for water treatment should be informed.

This type of operation is restricted to processes using rotation. During the sterilization of products in glass jars, scratches on the lids may appear rarely.

Before the modification, it will be necessary to carry out a survey of the machines. This can also be done during service work on the machines.

Investment pays within a few months: possible savings

The modification for the half-water-immersion process requires a budget starting at 10,000 €.

Reducing the steam consumption of i.e. 352 kg by 89 kg generates an economization of 7,832 € per year, assuming 40 € per ton and 2,200 batches per year.

Reducing the water consumption of i.e. 5,950 l by 1,749 l generates an economization of 15,388 € per year, assuming 4 € per m³ and 2,200 batches per year.